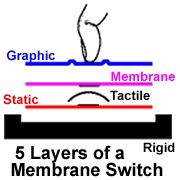

A Membrane Switch can be as simple as a two layer construction or a multi-layered complicated assembly. Regardless, as a momentary switch, must contain a Membrane Layer and a Static Layer.All other layers required for decoration, backlighting, adhesive, tactile response and rigid support are all optional.

Please see below a short explanation of five basic layers of a membrane switch:

1. GRAPHIC LAYER:

Decoration of a membrane switch is conventionally accomplished with thin, screen printed, polyester or polycarbonate. Elastomer is also a method of decorating a switch assembly and an attractive and functional alternative especially when a three dimensional look and feel is desired.

2. MEMBRANE LAYER:

As discussed above the Membrane Layer is thin & pliable and carries at least one of the poles of the switch or carries a conductive shorting pad. This is a required layer. Materials used are: Polyester, Metal Dome, Elastomer, Polyimide.

3. TACTILE LAYER:

There are several ways to create a tactile response, some are a result of forming another layer. For example a dome embossed polyester overlay means the graphic layer is also the tactile layer. If a poly dome is formed in the membrane layer means it doubles as the tactile layer. Obviously if the tactile layer is absent, you have a non-tactile membrane switch. Options for Tactile Layers are Metal Dome, Polyester Dome, Dome Emboss in the Graphic Layer, Elastomer.

4. STATIC LAYER:

The Static Layer is rigidly supported and carries at least one of the poles of the switch or carries a conductive shorting pad. The Static Layer is a required component of a membrane switch. Polyester, transparent conductor – ITO, Polyimide, Printed Circuit Board.

5. RIGID LAYER:

If the static layer is made from a flexible material it must be laminated to a rigid material. Many membrane switches are purchased without a rigid backer and the static layer does not become truly static until it is attached permanently to the instrument housing. Example materials: Aluminum, Steel, Plastic, Glass, Fiberglass

Ok, you can see the membrane switch construction as below: